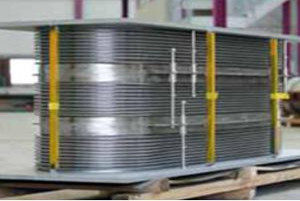

Expansion joints are devices that are used to allow for the heat-induced mitigation and expansion that takes place in various states of climate. These expansion joints offer an innovative and reliable solution for different types of application like power generation, power plants, shipbuilding, district heating, wind power, cement plant and many other industries. The joints offer a complete product range of metal expansion joints which ranges from low-pressure exhaust bellows to a complex engineered solution for fluid catalyst cracking units.

Handling of the Joints

The joints should not be lifted with ropes through the bolt holes. If it is required to lift these joints through the bore, then a saddle should be used to distribute the weight. These joints should not be kept vertically on the edges for any period.

Serving Conditions

The rating of the joints should be done by keeping in mind some of the factors like movement, pressure, and selection of materials that match the system requirement. If the system requirement exceeds those of the joint range, one should contact the manufacturer.

Alignment of these joints

Metallic expansion joints are not designed to make up the piping misalignment errors. In that scenario, one needs to check with the manufacturer if the piping misalignment is present.

Storage of the Joint

- The metallic expansion joint should be stored in cool, dry place such as a warehouse.

- The flange face should be down on the wooden platform.

- No bulky items should be stored on the top of the joints.

- In an ideal condition, these joints can provide a life expectancy of ten years.

Anchoring

The key function of these metallic expansion joints is to compensate the thermal expansion of the axial pipe. The metal expansion joints must have the protection of adequate anchoring against the thrust pressure of the media to prevent damage. Anchoring must be installed as close as possible to the joints with the originating equipment serving as equipment anchor. The anchors are installed to prevent the movement in any direction. Pipe pedestals or hangers are not considered as anchors since they offer no restriction against end motions.

At the time designing the anchors for these metal joints, one must consult the internal thrust force table. The weight of valves, media and piping and the resistance of the piping to deflection are required to be included as a part of strength and design weight of an anchor.

Metal expansion joints can be required to operate under very extreme conditions particularly when deployed in boiler seals or aircraft. The precision required of this equipment necessitates stringent testing before deployment in many systems.

To prevent undue strains being placed on expansion joints, manufacturers have developed several different support structures that can be deployed on a pipeline increasing the effectiveness of a given bellows. Some joints are fitted with internal liners or external sheaths to prevent damage to the main assembly, and external tie-rods or a universal joint called gimbals is fitted in some applications to prevent twisting, or excessive movement in any direction beyond design limitations.

Leave a Reply