An expansion joint represents a multitude of pieces, created to absorb any heat-induced expansion.

This device has also the role of absorbing any vibration or holding a larger construction’s parts together. Sometimes, it’s being used to allow a more facile movement in case of a ground settlement or earthquake. The expansions joints are becoming very popular because they provide safety, reliability and they behave well over time. They are being used in many modern structures and they are quickly becoming extremely popular. Without them, a large structure would eventually crack, because of the continuous vibration and stress induced.

The best thing about expansion joints is that they can be customized, according to the user’s needs. A professional company will take a close look at your project and will adapt their product to your particular needs. And we’re not only talking about the design feature. Some massive projects and structures, require a special level of attention and they need a stable expansion joint. The joint should be able to withstand all the pressure, and in the same time, keep all the parts together.

Because of logistical reasons, some of the large expansion joints are being manufactured right on site. The engineers will arrive at your site, making sure that the joints are going to be effective and sustainable for your future project.

The expansion joints are mostly used in bridge structures. Their design should be able to allow a continuous traffic, creating in a same time a smooth surface. A good producer like Kompaflex, will also consider the temperature variations and the structural strength. The expansion joints will stop the bridge from bending and will ensure a more simple maintenance of the parts. When the movements of any bridge exceed the capacity of a single gap. They are a little more complicated to manufacture but they ensure reliability and they can accommodate movements for any direction.

Railway expansion joints are being used when a railway runs over any bridge. If the bridge has no expansion, there will be a tiny gap between the railway and the bridge. However, this procedure is a little more complicated. Even if the expansion joint will bung the gap, it should still be able to provide a continuous surface for the train. This kind of project requires a special level of expertise, but a company like Kompaflex could do it for a cheap price.

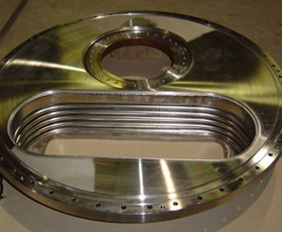

Another popular use of expansion joints is in pipes. Pipe expansions are extremely necessarily, especially in systems that have to take some big temperature variations. It mostly applies to dynamic systems, which are always under pressure and have to endure shock or intense vibrations. These types of joints require a special approach, and they are usually made by metal or glass fiber.

The joint is designed with the shape of a convolution, because it should be able to withstand the internal pressure of the pipe. However, the joint should not remain rigid and a certain level of flexibility is required. This type of expansions is also known as compensators, because the basically “compensate” for the thermal movement. Expansion joints are necessarily for every big structure. If you want quality and reliability, you have to work with a professional company.

Leave a Reply